Project Name: China Coal Mengda

Project process: pretreatment + air flotation + flocculation sedimentation

Water yield: 4000m 3/ h

Water source: coal mine water

Water quality: high content of suspended solids

Service time: October 2021

System operating conditions

Polyacrylamide test report of Shandong Dahu New Material Co., Ltd

1. Experimental principle

Take water from the mine water regulating tank, add polyaluminium chloride, add dissolved and diluted anionic polyacrylamide, and observe its sedimentation rate, floc production and size, floc sedimentation rate and supernatant clarification.

2. Experimental reagent

Polyaluminium chloride

Anionic polyacrylamide

3. Experimental steps

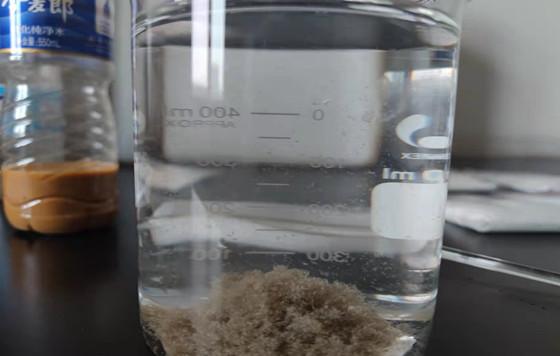

Take 500ml of mine water, add polyaluminium chloride, stir for 30s, and then add anionic polyacrylamide; According to the dosage of 3ppm, it is added to the water added with polyaluminium chloride. The results are shown in the figure

4. Experimental results:

Anionic polyacrylamide and polyaluminium chloride have obvious solid-liquid separation surface, the upper water is clear, the reagent matches the on-site water quality and can meet the needs of on-site production.

effect

Polyaluminium chloride and anionic polyacrylamide of Shandong Dahu New Material Co., Ltd. operate well in coal mine wastewater, effectively remove suspended solids in the water and ensure that the effluent quality meets the environmental protection operation specified by the state.

Real scene of the project site